Heat sealing is a critical aspect of packaging, especially in industries like food production, where maintaining product quality, safety, and freshness is essential. For manufacturers looking for reliable, high-performance packaging materials, AAE Barrier Film stands out for its excellent heat sealing performance. But what exactly makes heat sealing so important, and how does AAE Barrier Film excel in this area? In this article, we explore the significance of heat sealing in packaging and why AAE Barrier Film is a top choice for businesses seeking quality, efficiency, and safety in their products.

Heat sealing refers to the process of joining two layers of material by applying heat and pressure, which results in a strong, airtight seal. This process ensures that the contents inside packaging stay fresh, protected from external elements like moisture and oxygen, and maintain their integrity over time. A successful heat seal creates a barrier that keeps the product secure and extends its shelf life—critical factors for food manufacturers and exporters who need to deliver products to market without compromising quality.

One of the standout features of AAE Barrier Film is its ability to withstand demanding conditions in heat sealing. Whether it's for high-temperature boiling at 200°C, steaming at 121°C, or even low-temperature storage at -18°C, AAE Barrier Film performs reliably across a wide range of temperatures. This flexibility in sealing performance ensures that products packaged with AAE Barrier Film can endure various processing methods without the risk of compromising the seal, protecting the product inside, and ensuring that it reaches the consumer in optimal condition.

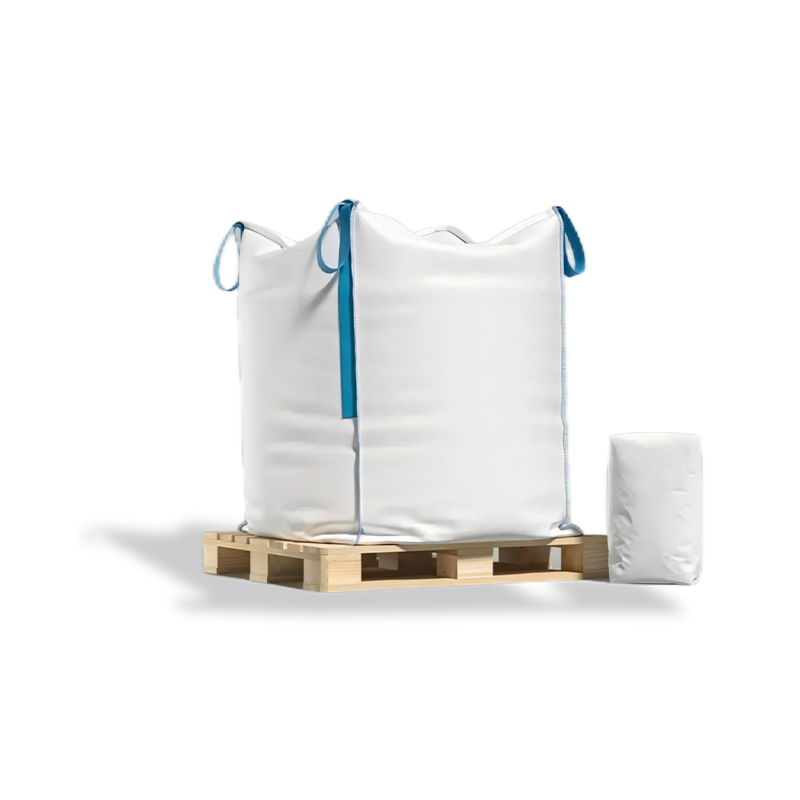

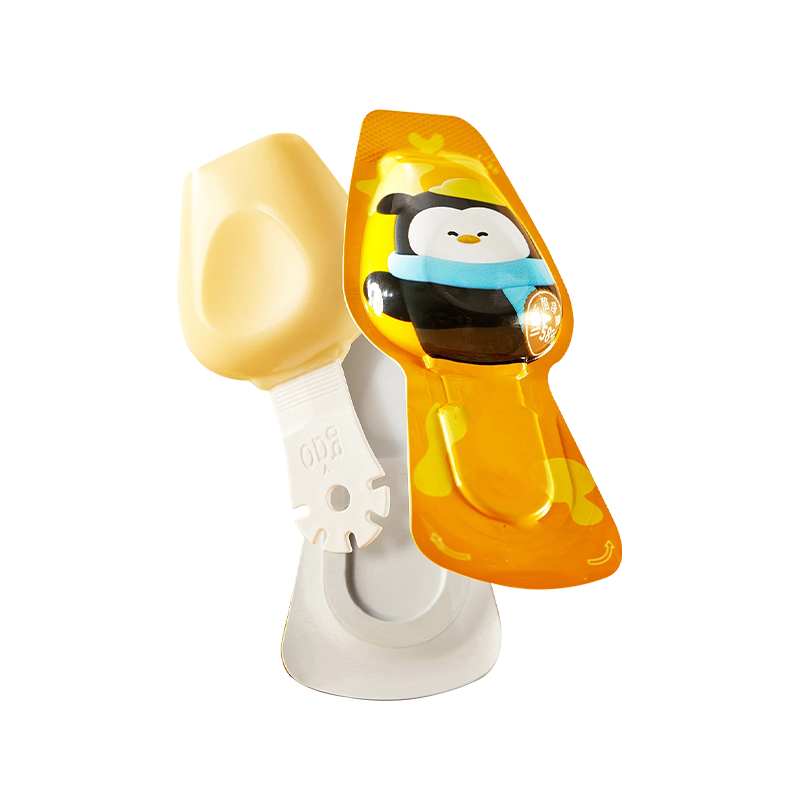

In addition to its robust performance at different temperatures, AAE Barrier Film offers excellent barrier properties, preventing the ingress of oxygen and moisture. This makes it particularly valuable in the food industry, where freshness is key. Foods such as snacks, ready-to-eat meals, and frozen items benefit greatly from AAE Barrier Film, as it helps maintain flavor, texture, and nutritional value over time. The film’s superior sealing capabilities enhance this protection by ensuring that the barrier stays intact, even in challenging storage and transport conditions.

Another advantage of using AAE Barrier Film for heat sealing is its versatility. The film can be customized to meet specific needs by adjusting thickness and PA content, providing tailored solutions for various product types. Whether it's for high-end food packaging or industrial applications, AAE Barrier Film can meet the exact specifications required, ensuring an airtight seal that protects the product while offering a smooth, clear, and attractive packaging appearance. This level of customization makes it an excellent choice for businesses that prioritize both function and aesthetics.

For manufacturers, the consistent heat sealing performance of AAE Barrier Film translates into greater efficiency and fewer product recalls or returns. With fewer instances of seal failures, businesses can rely on AAE Barrier Film to ensure that each product arrives at its destination safely. This reliability not only helps companies maintain a strong reputation but also reduces the costs associated with packaging errors, further emphasizing the value of investing in high-quality materials for food and other sensitive products.

In conclusion, AAE Barrier Film’s exceptional heat sealing capabilities make it an invaluable asset for businesses in the food industry and beyond. By offering protection against temperature fluctuations, moisture, and oxygen, the film ensures the integrity and freshness of the products inside. Its versatility and performance across a range of temperatures make it a top choice for manufacturers looking to optimize their packaging solutions, while its customization options ensure that every product is packaged to meet the specific needs of the market. With AAE Barrier Film, businesses can enhance the quality, shelf life, and appeal of their products, ultimately delivering a superior experience to consumers.

LANGUAGE

LANGUAGE

English

English 中文简体

中文简体