In what aspects does FIBC Liners High Performance Film have outstanding performance?

FIBC liners with high-performance film stand out in the realm of bulk material packaging due to their remarkable performance across various critical aspects. These innovative liners, leveraging advanced materials and engineering, offer a suite of benefits that elevate them as the preferred choice for industries requiring robust, reliable, and protective packaging solutions.

One of the key areas where

FIBC liners high-performance film excel is in their unparalleled strength and durability. These liners are engineered to withstand rigorous handling, heavy loads, and challenging environments without succumbing to tears or punctures easily. The high-performance film used in these liners is specially designed to provide exceptional tensile strength and impact resistance, ensuring the safe transportation and storage of bulk materials even in demanding conditions.

The barrier properties of high-performance film in FIBC liners are another standout feature. These films offer excellent protection against moisture, oxygen, UV light, and other environmental factors that can compromise the quality and integrity of stored materials. By creating a robust barrier, FIBC liners with high-performance film safeguard the contents from contamination, spoilage, and degradation throughout the supply chain, preserving product quality and extending shelf life.

Industries dealing with hazardous materials benefit greatly from FIBC liners with high-performance film due to their exceptional chemical resistance. The specialized film is engineered to resist a wide range of chemicals, including acids, alkalis, solvents, and oils, ensuring that the liners maintain their integrity and prevent leaks or spills that could lead to safety hazards or environmental damage.

High-performance films used in FIBC liners exhibit remarkable temperature stability, allowing them to maintain their properties and performance across a broad range of temperatures. Whether handling hot materials in industrial processes or storing temperature-sensitive products, these liners offer reliability and protection, minimizing the risk of thermal damage or degradation.

Despite their robustness, FIBC liners with high-performance film remain flexible and adaptable. This flexibility allows the liners to conform to the shape of bulk containers, facilitating efficient filling, handling, and discharge of materials. The ability to maintain form while offering superior protection makes these liners ideal for a wide range of applications across diverse industries.

The tear and impact resistance of

FIBC liners high-performance films contribute significantly to the overall performance of FIBC liners. These films are engineered to withstand tears, punctures, and impacts, ensuring that the liners retain their structural integrity even under challenging conditions. This resilience reduces the risk of product loss, containment breaches, and potential safety hazards during transportation and storage.

FIBC liners with high-performance film are designed for compatibility with various filling and discharging methods, including gravity filling, pneumatic filling, and mechanical conveying systems. Moreover, they can be customized to fit different types and sizes of bulk containers, enhancing their versatility and applicability across different industries and packaging requirements.

Can used FIBC Liners High Performance Film be recycled or disposed of properly?

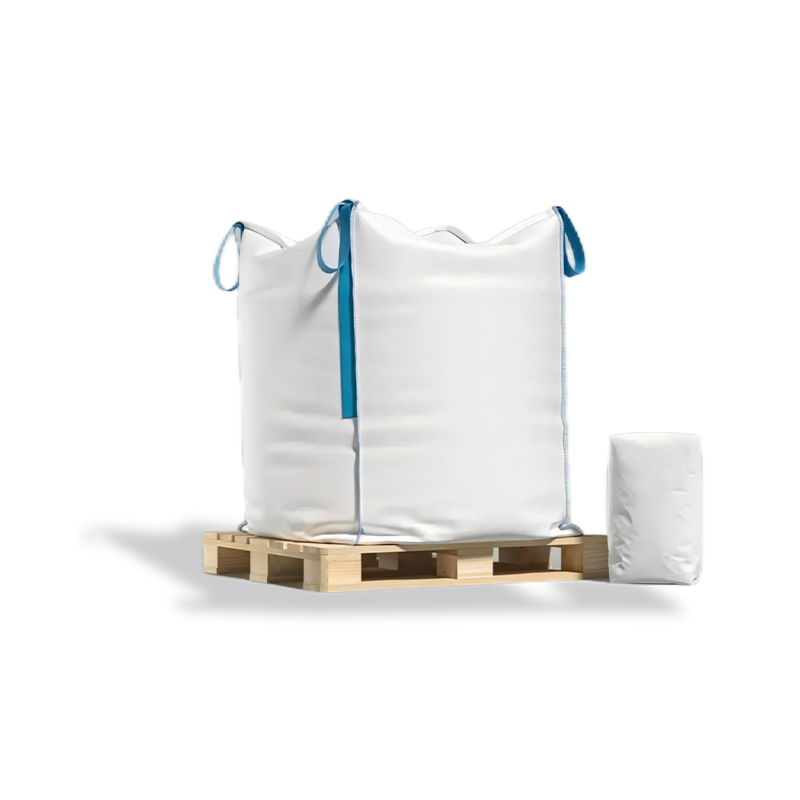

Flexible Intermediate Bulk Containers (FIBC), commonly known as bulk bags, play a crucial role in various industries for storing and transporting bulk materials such as grains, chemicals, and minerals. These bags often come with liners made from high-performance films to enhance durability, prevent leakage, and protect the contents from external elements.

High-performance films used in FIBC liners can be composed of different materials such as polyethylene (PE), polypropylene (PP), or specialized plastics. These materials offer superior strength, tear resistance, and barrier properties, making them ideal for industrial packaging applications. It's crucial to identify the specific material composition of the FIBC liner to determine the appropriate recycling or disposal methods.

Recycling FIBC liners made from high-performance films is feasible in many cases, especially when they are composed of commonly recyclable plastics like PE or PP. Look for recycling symbols or codes on the liner's packaging to identify the material type. Local recycling centers may accept these materials, but it's essential to check their policies and guidelines regarding industrial packaging recycling.

Some key points to consider for recycling FIBC liners include:

Cleanliness: Ensure that the liners are free from contaminants and residues before recycling. Remove any leftover materials or debris to improve recyclability.

Separate Collection: Some recycling facilities may require separate collection of FIBC liners due to their size and nature. Follow guidelines for proper collection and transportation to recycling centers.

Material Compatibility:

FIBC liners high-performance films made from PE or PP are more commonly accepted for recycling. Verify with recycling facilities if they can process these materials effectively.

Specialty Recycling Programs: Explore specialized recycling programs or partnerships that focus on industrial packaging materials. These programs may offer more efficient recycling solutions for FIBC liners.

Disposal Methods for Non-Recyclable FIBC Liners:

If recycling is not a viable option or the FIBC liners are composed of materials that are not easily recyclable, proper disposal is essential to minimize environmental impact. Here are some disposal methods to consider:

Landfill Disposal: Sending non-recyclable FIBC liners to authorized landfills is a common disposal method. Follow local waste management regulations for proper landfill disposal procedures.

Waste-to-Energy Facilities: Some regions have waste-to-energy facilities that can process industrial packaging materials, including FIBC liners. Check if such facilities are available and comply with their disposal requirements.

Consult with Experts: If you're unsure about the disposal methods for specific FIBC liners, consult with waste management experts or environmental agencies. They can provide guidance based on local regulations and best practices.