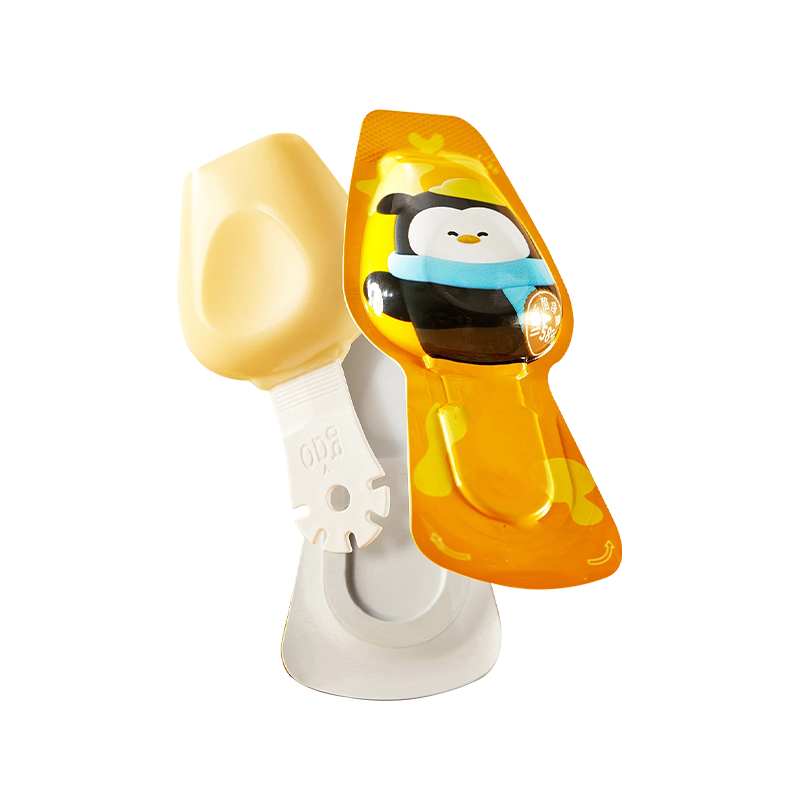

In the competitive world of food and beverage packaging, maintaining product integrity is paramount. One of the most effective solutions in this regard is the EOE-Based Printed Laminated Film Membrane, a material that combines convenience, branding potential, and crucial protective functions. Among these, barrier properties stand out as a key factor in preserving freshness and extending shelf life. These membranes are not simply aesthetic wrappers—they are complex multi-layered structures engineered to control gas exchange, moisture ingress, light exposure, and mechanical stress, all of which influence the condition of the packaged product over time.

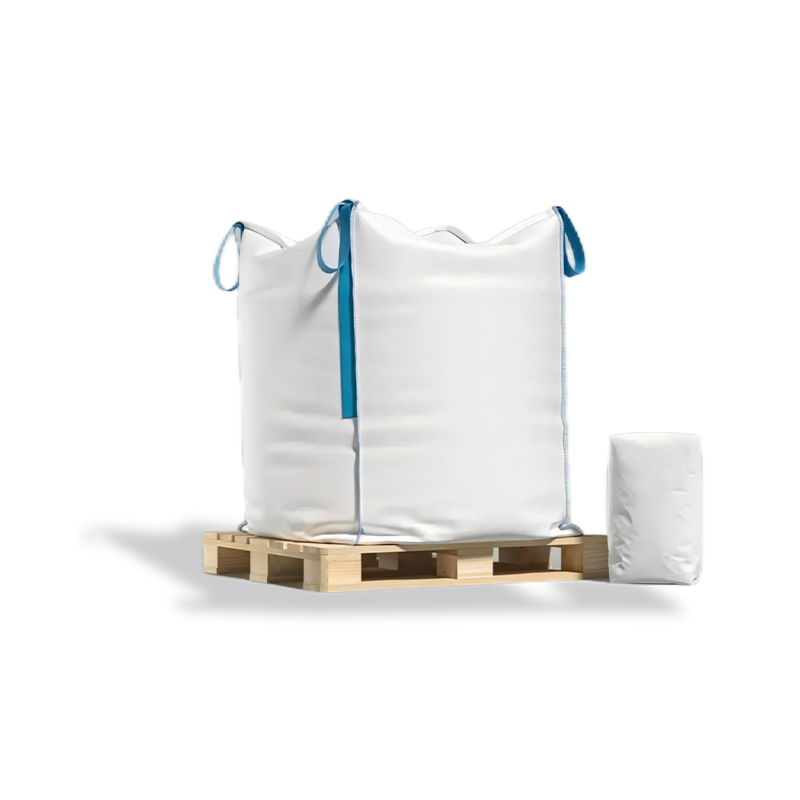

Barrier properties are primarily evaluated through oxygen transmission rate (OTR) and water vapor transmission rate (WVTR). A low OTR prevents oxidation, which is vital for products containing oils or fats, as it helps prevent rancidity. A low WVTR, on the other hand, maintains texture and taste by blocking humidity from penetrating the package. These characteristics are especially important in applications like ready-to-eat meals, dried goods, and powdered ingredients, where any compromise in barrier function can quickly lead to spoilage. High-barrier films, often utilizing aluminum foil or metalized PET layers, are chosen for these applications to ensure optimal shelf performance.

However, balancing barrier strength with other performance attributes—such as flexibility, heat resistance, and sealability—is a technical challenge. The EOE-Based Printed Laminated Film Membrane must also bond effectively with the easy-open end, typically a metal component. This fusion between rigid and flexible materials demands precise lamination and sealing technologies, ensuring a tight seal while still enabling consumer convenience. Film formulations may include layers of PET, PA, PE, or EVOH, each selected for specific barrier and mechanical properties. Engineers must carefully calibrate thickness, material sequencing, and adhesive compatibility to optimize both protection and usability.

Not to be overlooked is the role of surface treatments and coatings. Anti-fog layers, UV-blocking additives, and aroma barriers can be integrated into the film to enhance performance in specific markets. For instance, snack foods might require strong aroma retention, while dairy packaging often demands excellent UV protection to prevent nutrient degradation. These additions are tailored based on the nature of the product, storage environment, and expected distribution cycles. Our experience in customizing laminated structures to match these variables is what helps our clients reduce product returns and improve end-user satisfaction.

Furthermore, it's essential to consider how barrier properties affect production efficiency and packaging line compatibility. High-barrier films can sometimes reduce sealing speeds or increase waste if not correctly matched to equipment settings. That’s why our technical support team works closely with clients to conduct line trials and performance simulations. This collaborative approach not only ensures barrier integrity but also boosts operational efficiency—because high-performance packaging must perform just as well on the production floor as it does on the shelf.

At the same time, the visual and branding aspects of the EOE-Based Printed Laminated Film Membrane cannot be ignored. Printing on barrier films requires careful ink selection and registration to avoid affecting barrier performance. Using advanced printing techniques, we ensure that the protective layers remain intact while delivering sharp, vibrant visuals that resonate with end users. This combination of functionality and market appeal is what gives our packaging a distinct competitive edge.

In an industry where freshness equals brand value, investing in barrier-optimized packaging isn’t just smart—it’s essential. Whether you’re launching a new product or upgrading existing packaging formats, our expertise in EOE-Based Printed Laminated Film Membrane technology is ready to support your goals. With tailored solutions that meet the demands of both logistics and shelf appeal, we help brands deliver quality from production line to consumer table.

LANGUAGE

LANGUAGE

English

English 中文简体

中文简体