The production of EVOH-based films is a precise and highly efficient process, offering a range of benefits that make them an ideal choice for a variety of packaging applications. One of the key advantages of EVOH-based films lies in their one-step blown film process, which simplifies production and ensures high-quality results with minimal waste. This method allows for the creation of films with superior barrier properties, essential for industries that require airtight and moisture-resistant packaging, such as the cosmetics and pharmaceutical sectors. By streamlining the manufacturing process, the production of EVOH-based films remains not only efficient but also cost-effective, allowing for faster turnaround times and greater scalability for businesses.

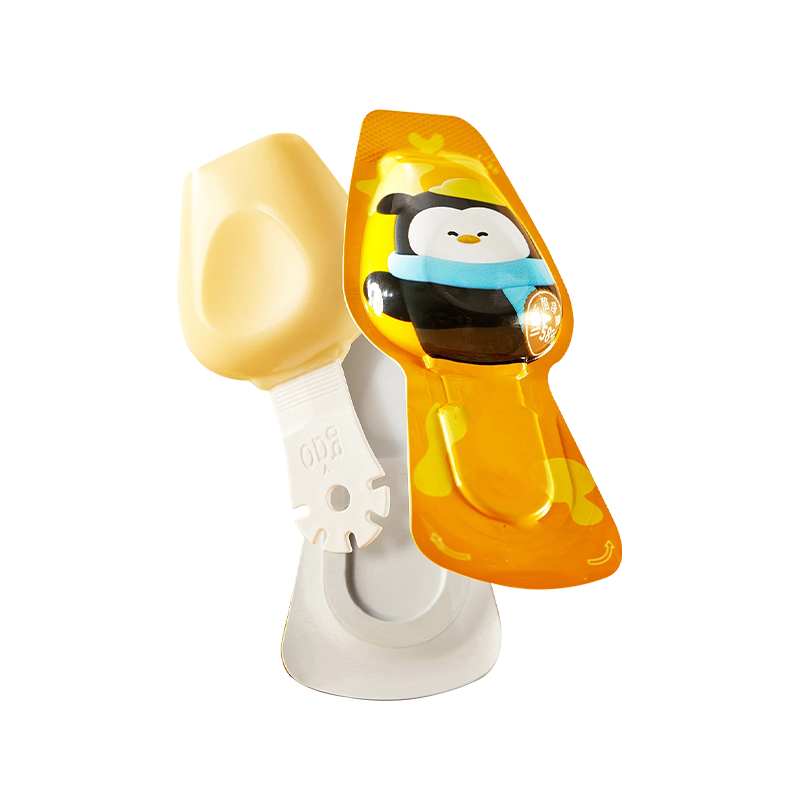

Customization is another significant factor that sets EVOH-based films apart from other materials. Unlike traditional packaging films, EVOH films offer a high degree of flexibility, with the thickness and EVOH ratio easily adjustable according to the specific needs of each client. Whether the requirement is for a lightweight packaging solution or a more robust film with increased barrier performance, EVOH-based films can be tailored to meet these demands. This versatility makes them suitable for various products, from toothpaste tubes to ointments and cosmetics, ensuring that the packaging will perform optimally throughout its lifecycle. Clients can choose the exact specifications that align with their product’s needs, making EVOH films an adaptable choice for businesses across multiple industries.

In terms of technical performance, the one-step blown film process used in EVOH production offers consistent, high-quality results every time. This manufacturing technique reduces the likelihood of defects and ensures that each roll of film meets stringent industry standards for barrier properties. The ability to customize the thickness and EVOH content further enhances the film’s performance, especially in terms of moisture vapor transmission rates (WVTR) and oxygen transmission rates (OTR), two critical factors that directly affect product preservation. When it comes to packaging sensitive goods like cosmetics or medications, ensuring that the product is protected from external contaminants is paramount. EVOH-based films provide that protection through their superior barrier properties, contributing to extended shelf life and improved product integrity.

Another benefit of EVOH-based films is their ability to meet the stringent safety requirements set by global certification bodies. From APR (Association of Plastic Recyclers) compliance to meeting FDA and EU standards, these films are manufactured with quality and safety in mind. For companies operating in industries like cosmetics, pharmaceuticals, and food packaging, compliance with such certifications is not optional—it’s essential. The EVOH films meet these requirements, ensuring that businesses can rely on a packaging solution that aligns with both regulatory standards and consumer expectations. This focus on quality assurance is a key reason why EVOH-based films are gaining popularity among manufacturers who need packaging solutions they can trust.

The efficiency of the one-step blown film process also plays a critical role in reducing production time and costs. With faster lead times and minimal need for additional steps, EVOH films are an excellent choice for businesses that require reliable packaging solutions without sacrificing performance or quality. This efficient production method ensures that clients receive a consistent product at scale, whether they’re producing small batches or large volumes. Furthermore, the uniformity of the film across all rolls guarantees that businesses can maintain a high level of packaging quality for every product shipped, whether it’s for local or international markets.

As the packaging industry continues to evolve, EVOH-based films stand out as a smart and sustainable choice for businesses looking to stay ahead of the curve. Their combination of excellent barrier properties, customization options, and efficient production process make them a powerful solution for a range of packaging needs. With the increasing demand for eco-friendly and compliant packaging solutions, EVOH-based films offer an opportunity for manufacturers to enhance their product offerings while also meeting the growing consumer demand for sustainability. Whether you are looking to replace ABL (Aluminum Barrier Laminate) or simply seeking a high-performance, recyclable alternative, EVOH-based films provide a versatile and reliable packaging solution.

LANGUAGE

LANGUAGE

English

English 中文简体

中文简体